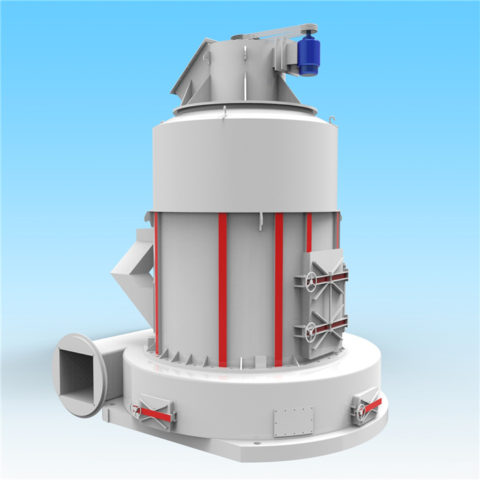

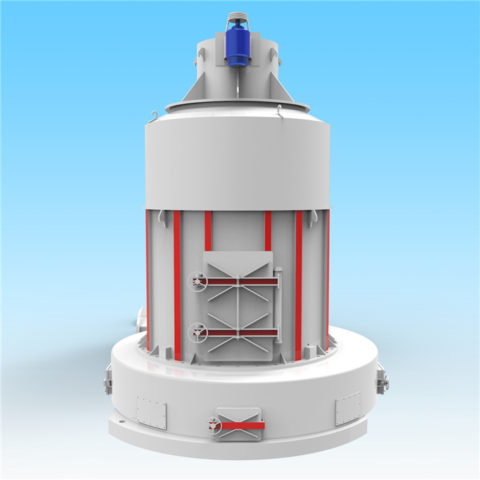

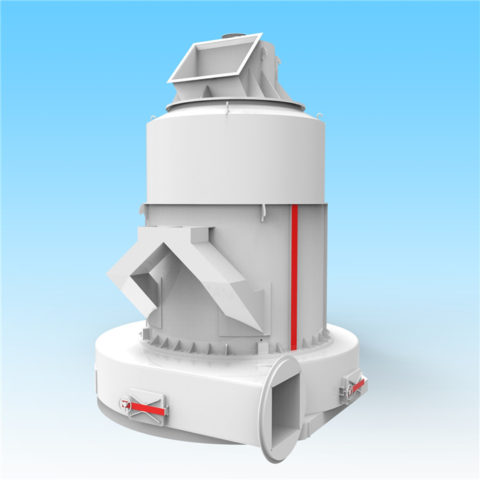

Description

| Feature | Description |

|---|---|

| High Output & Low Consumption | The largest model of Raymond mill in China, providing equal capacity with the vertical mill. |

| Less Floor Space | Requires only 140 sq.m. of floor space, excluding the warehouse area for raw material and final product storage. |

| Large Transmission Capacity | Blower utilizes a high-pressure centrifugal fan to increase air volume and pressure, significantly enhancing pneumatic conveying capabilities. |

| High Collecting Efficiency | Cyclone collector features parallel double cyclone design, offering 10-15% higher collection efficiency compared to single cyclone systems. |

| High Classifying Capacity | Classifier incorporates a built-in large taper blade turbine, allowing adjustable outlet fineness ranging from 80-600 mesh. |

| Strong Ability of Shoveling Material | Equipped with super large shovel blade to maximize material shoveling into the grinding area between the roll and ring. |

| Energy-conservation and Environment-protection | Pulse dust collector installed in the surplus wind outlet achieves collection efficiency of up to 99.9%, ensuring a healthy workshop environment. |

| Driving System Improved | Utilizes German Flender technology for enhanced driving system stability and reliability. Features large torque force, compulsive lubrication for bearings, water cooling for the cooling system, and simple oil filter cleaning. |

Reviews

There are no reviews yet.