10 Crucial Factors to Consider When Choosing the Perfect Hydraulic Pump: Powering Your Industrial Success

The lifeblood of countless industrial machines, the hydraulic pump plays a vital role in transferring and amplifying fluid power. From powering construction equipment to operating complex manufacturing machinery, selecting the right hydraulic pump is essential for ensuring optimal performance, efficiency, and longevity of your equipment. However, navigating the vast array of hydraulic pump options available in the market can be overwhelming. Fear not! This comprehensive guide will equip you with the knowledge to make an informed decision, highlighting the expertise of Top Machineries along the way.

Understanding Your Hydraulic Pump Needs

The first step to selecting the perfect pump is to gain a clear understanding of your specific application requirements. Here are some key factors to consider:

- Flow Rate: This refers to the amount of fluid the pump can deliver per unit time, typically measured in liters per minute (LPM) or gallons per minute (GPM). Your application will dictate the required flow rate to power your equipment efficiently.

- Operating Pressure: The pressure rating of your pump needs to match the maximum pressure required by your hydraulic system to avoid malfunctions. Consider factors like workload demands and peak pressure spikes.

- Fluid Type: Different types of hydraulic fluids have varying properties. Choose a pump compatible with the fluid you intend to use, considering factors like viscosity and compatibility with pump materials.

- Power Source: Hydraulic pumps can be powered by electric motors, internal combustion engines, or other means. Select a power source that aligns with your available resources and operational environment.

Essential Considerations for Choosing a Pump

While the above factors are crucial, a well-informed decision requires delving deeper into these key aspects:

- Efficiency: A high-efficiency hydraulic pump minimizes energy consumption, leading to lower operating costs. Consider pump designs that minimize internal losses and prioritize energy transfer.

- Noise Levels: In some work environments, noise reduction is a critical factor. Explore options for quieter pump models or noise suppression solutions if noise levels are a concern.

- Reliability and Durability: A reliable pump ensures consistent performance and minimizes downtime. Choose a pump built with robust materials and a proven track record for reliability in demanding applications.

- Maintenance Requirements: Consider the ease and frequency of required maintenance for the chosen hydraulic pump. Opt for pumps with readily available replacement parts and user-friendly maintenance procedures.

Selecting the Right Pump Type for Your Needs:

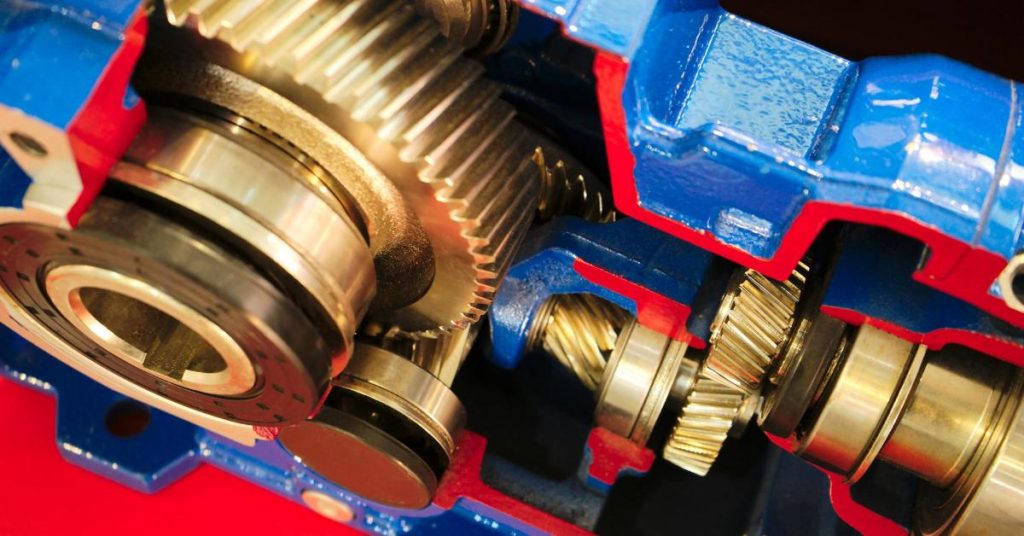

The world of hydraulic pumps encompasses a diverse range of types, each with its own strengths and applications. Here’s a brief overview of some common types to consider:

- Gear Pumps: Known for their simple design, reliability, and affordability, gear pumps offer a good balance of flow rate and pressure for moderate-duty applications.

- Vane Pumps: Vane pumps offer high efficiency and smooth operation, making them suitable for applications requiring precise control and variable flow rates.

- Piston Pumps: Piston pumps deliver high pressure capabilities and are ideal for demanding applications like construction equipment or heavy machinery.

Why Choose Top Machineries as Your Hydraulic Pump Partner?

At Top Machineries, we understand the critical role pumps play in keeping your industrial operations running smoothly. Here’s how we empower you to select the perfect pump for your needs:

- Unmatched Selection of Hydraulic Pumps: We offer a comprehensive selection of high-quality hydraulic pumps from leading manufacturers, catering to diverse flow rate, pressure, and power source requirements.

- Expert Application Specialists: Our team of experienced application specialists will work closely with you to understand your specific needs and recommend the ideal pump type and configuration for optimal performance in your application.

- Technical Support and System Design Expertise: Our team can assist with system design considerations, ensuring your chosen pump integrates seamlessly with your existing hydraulic system.

- Reliable After-Sales Support: We provide comprehensive after-sales support, including spare parts availability, preventative maintenance programs, and technical assistance to ensure your hydraulic pump operates at peak performance for years to come.

Conclusion

Choosing the right hydraulic pump is a crucial decision that impacts the efficiency, performance, and overall success of your industrial operations. By considering all the essential factors, from application requirements to pump type and maintenance needs, you can ensure an informed purchase. Partnering with a reputable hydraulic pump supplier like Top Machineries provides you with the expertise, selection, and support you need to find the perfect hydraulic pump to power your industrial success. Visit us today to explore our extensive range of hydraulic pumps and get expert advice on selecting the ideal solution for your specific needs!

0 Comments