In the quest for sustainable energy solutions, biomass gasification systems stand out as a pivotal technology. Designed to transform organic materials into a renewable source of energy, biomass gasification systems and shredding equipment are revolutionizing how we approach power generation. This article emphasizes the mechanics and benefits of this innovative technology, which converts wood chips, agricultural residues, and other biomass materials into combustible gases used for generating electricity. See action on social media.

Biomass Gasification: A Thermochemical Conversion Process

Biomass gasification is a transformative process that converts organic materials, such as agricultural waste, wood chips, and other biomass, into a valuable source of energy known as syngas or synthetic gas. This is achieved through a thermochemical process, which takes place under high temperatures in an environment with restricted oxygen availability. Unlike combustion, which fully oxidizes the material, biomass gasification systems partially oxidize the biomass, allowing it to decompose into a mixture of carbon monoxide, hydrogen, and a smaller amount of carbon dioxide, along with trace gases. This controlled environment ensures efficient conversion while preventing the complete combustion of the biomass.

At the Core: The Gasifier Unit in Biomass Gasification Systems

At the core of a biomass gasification system is the gasifier, where the biomass is heated to temperatures typically between 800°C and 1400°C. In this environment, the organic material undergoes several chemical reactions. Initially, thermal decomposition, or pyrolysis, breaks down the biomass into solid charcoal and volatile gases. Subsequently, the charcoal is further reacted in a reduction process, where it interacts with the limited oxygen and steam generated within the gasifier. These reactions produce the syngas, which, due to its combustible nature, can be used directly to fuel engines or turbines to generate electricity.

The Versatility of Biomass Gasification Systems

The versatility of syngas makes biomass gasification systems a particularly appealing technology for sustainable energy production. The gas can be used immediately for power generation, or it can be cooled and cleaned to remove contaminants before being utilized in various applications, including as a substitute for natural gas or as a feedstock for producing liquid biofuels. Moreover, by converting biomass waste into energy, gasification helps reduce landfill use and greenhouse gas emissions, aligning with environmental goals and contributing to a more sustainable energy future.

Components of a Biomass Gasification System

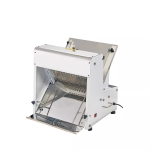

Biomass Shredder: Ensuring Efficient Conversion

The biomass shredder is a crucial first step in the biomass gasification system, serving the essential function of preparing the biomass for efficient conversion. By breaking down large pieces of organic material into smaller, more uniform sizes, the shredder ensures that the biomass can be fed consistently into the gasifier. This uniformity is critical because it allows for more even heat distribution during gasification, leading to a more efficient and complete conversion of the biomass into syngas.

Additionally, smaller particles have a greater surface area relative to their volume, which accelerates the chemical reactions during gasification. This not only maximizes the energy output from the biomass but also reduces waste by ensuring that a higher percentage of the material is converted into usable energy.

Gasifier Unit: The Heart of the Biomass Gasification System

At the heart of the biomass gasification systems lies the gasifier unit, where the actual transformation of solid biomass into syngas occurs. This component operates at high temperatures, typically between 800°C and 1400°C, and under controlled oxygen levels to facilitate the thermochemical conversion processes. The limited oxygen environment is essential to prevent the biomass from burning completely, instead allowing it to thermally decompose and release volatile gases. These gases are then further reacted within the gasifier through a series of complex chemical reactions, resulting in the production of syngas.

The syngas produced is a combustible mixture of carbon monoxide, hydrogen, and trace amounts of carbon dioxide and methane, which can be directly utilized to generate electricity through internal combustion engines or turbines. Furthermore, the flexibility of the gasifier unit to process a variety of biomass inputs makes it a versatile solution adaptable to different geographic and industrial contexts.

Cleaning and Cooling Systems: Ensuring Syngas Quality

Following the production of syngas in biomass gasification systems, it is crucial to ensure its purity and suitability for energy generation or further processing. The cleaning and cooling systems play a pivotal role in achieving this. These systems remove particulate matter, tar, and other impurities from the syngas, which could otherwise damage downstream equipment such as engines and turbines used in power generation.

Cleaning the syngas not only protects the equipment but also improves the efficiency of the power generation process. Cooling is equally important as it condenses excess steam and adjusts the temperature of the syngas to optimal levels for either storage or immediate use. By enhancing the quality of the syngas, these systems ensure that the gas meets regulatory standards for emissions and achieves high efficiency in power generation.

Benefits of biomass gasification

- Enhanced Efficiency of Energy Conversion:

Biomass gasification systems stands out for its superior efficiency in converting the inherent energy content of biomass into a usable form of gas, far surpassing the capabilities of traditional combustion technologies. This efficiency is achieved through the process of thermochemical conversion, where biomass is not merely burned but chemically transformed into syngas—a mixture of hydrogen, carbon monoxide, and trace gases. Syngas has a high energy content and can be used directly in turbines or engines to generate electricity or further processed into liquid fuels or chemicals. This high conversion efficiency means that more of the biomass’s potential energy is harnessed, making gasification a highly effective technology for energy extraction. - Significant Reduction in Environmental Impact:

One of the most compelling benefits of biomass gasification systems is its ability to mitigate environmental impacts, particularly in terms of greenhouse gas emissions. Unlike fossil fuels, biomass is considered carbon-neutral. This is because the carbon dioxide released during the gasification process is roughly equivalent to the amount absorbed by the plants during their growth phase, creating a balanced carbon cycle. Furthermore, by diverting biomass from landfills where it would decompose anaerobically to produce methane—a potent greenhouse gas—gasification helps reduce overall emissions. The cleaner technology of gasification also results in fewer pollutants such as sulfur oxides and nitrogen oxides compared to traditional combustion methods. - Versatility and Scalability:

Biomass gasification systems technology is highly versatile and scalable, making it suitable for a wide range of applications—from small local systems to large industrial plants. This scalability is beneficial for adapting to different energy needs and conditions. For instance, small modular gasification units can be used in rural or remote areas to process local biomass resources, providing a reliable source of energy where traditional power grids are unavailable. On the larger scale, industrial biomass gasification systems plants can generate significant amounts of energy, contributing to the utility grid and supporting larger communities. This flexibility allows for the customization of gasification plants to meet specific requirements, optimizing both their economic and environmental impact. - Effective Waste Reduction:

Biomass gasification systems significantly contributes to waste reduction by utilizing organic materials that would otherwise contribute to landfill mass. Agricultural residues, wood chips, and other organic waste materials are ideal feedstocks for gasification. By converting these materials into energy, gasification helps reduce the volume of waste sent to landfills, decrease methane emissions from decomposition, and repurpose waste into a valuable resource. This not only helps manage waste more effectively but also taps into an underutilized resource, promoting a more sustainable approach to waste management and energy production.

Contact TopMachineries today to discuss your needs. We offer a wide range of industrial equipment and parts. Send a message to product.

0 Comments