2024 Guide: How Food and Beverage Manufacturers Can Benefit from Choosing the Right Industrial Food Processing Equipment Supplier

In the ever-evolving food and beverage industry, the importance of efficiency, safety, and product quality cannot be overstated. As consumer demands grow and regulations become increasingly stringent, food and beverage manufacturers are constantly seeking ways to enhance their operations. One critical decision that can have a profound impact on your business is selecting the right industrial food processing equipment supplier. This guide will explore the benefits of partnering with the right supplier and provide essential tips to help you make an informed choice in 2024.

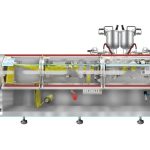

The Importance of Industrial Food Processing Equipment

The backbone of any food and beverage manufacturing operation lies in its equipment. Industrial food processing equipment plays a crucial role in every stage of production—from mixing and blending to cooking, packaging, and labeling. This machinery ensures that your products are made to consistent quality standards, with minimal waste and maximum efficiency.

Why Choosing the Right Supplier Matters

Selecting the right industrial food processing equipment supplier is not just about purchasing machines; it’s about forming a partnership that can support your business’s growth and success. Here are five key reasons why choosing the right supplier matters:

- Compliance with Hygiene Standards

The food and beverage industry is subject to strict hygiene and safety regulations. The right supplier will provide equipment that meets these standards, ensuring that your products are safe for consumption and reducing the risk of contamination. Look for suppliers that offer equipment with easy-to-clean designs, made from food-grade materials. - Enhanced Production Efficiency

In today’s competitive market, efficiency is key. Industrial food processing equipment must be reliable, easy to operate, and capable of handling high volumes. The right supplier will offer machinery that not only meets your current needs but also has the flexibility to adapt to future demands, helping you maintain a competitive edge. - Waste Reduction

Waste is a significant concern in the food and beverage industry, not just in terms of environmental impact but also in cost management. High-quality processing equipment can reduce waste by ensuring precise measurements, consistent mixing, and accurate portioning. A good supplier will work with you to understand your production process and recommend equipment that minimizes waste. - Cost-Effectiveness and Return on Investment

While the initial cost of industrial food processing equipment can be high, it’s essential to consider the long-term benefits. The right supplier will provide durable, efficient machines that offer a good return on investment through reduced downtime, lower maintenance costs, and higher production rates. Additionally, they may offer financing options or after-sales support to make the purchase more manageable. - Tailored Solutions for Your Specific Needs

Every food and beverage manufacturer has unique requirements based on their product lines, production volumes, and market demands. The right supplier will offer customized solutions that fit your specific needs, whether it’s a high-speed packaging line for a large-scale operation or a compact mixer for a boutique producer. They should also provide ongoing technical support and training to ensure you get the most out of your equipment.

Key Factors to Consider When Choosing an Industrial Food Processing Equipment Supplier

With so many suppliers in the market, how do you choose the right one for your business? Here are some essential factors to consider:

- Reputation and Experience

Look for suppliers with a proven track record in the food and beverage industry. Check customer reviews, ask for references, and research their history to ensure they have the experience and expertise to meet your needs. - Product Range and Quality

A good supplier should offer a wide range of high-quality equipment that covers all aspects of food processing, from preparation to packaging. Ensure that their products meet industry standards and are made from durable, food-safe materials. - Technical Support and After-Sales Service

Industrial food processing equipment is a significant investment, and you’ll want to ensure that your supplier offers comprehensive after-sales service, including installation, maintenance, and repairs. Check if they provide training for your staff and if they have a responsive customer support team. - Flexibility and Customization

Your production needs may change over time, so it’s crucial to work with a supplier that offers flexible solutions and can customize equipment to fit your specific requirements. - Cost and Financing Options

While price shouldn’t be the only factor, it’s important to find a supplier who offers competitive pricing and financing options that suit your budget. Look for transparency in their pricing and a clear understanding of the total cost of ownership.

Conclusion: Investing in the Future of Your Business

In the food and beverage industry, the right industrial food processing equipment can be the difference between success and failure. By partnering with a reliable supplier, you can ensure that your operations run smoothly, your products meet the highest standards, and your business remains competitive in 2024 and beyond.

Take your food and beverage manufacturing to the next level

Contact Top Machineries today to learn more about our state-of-the-art industrial food processing equipment and how we can help you achieve your production goals. Let’s build a successful partnership that drives your business forward!

0 Comments