Description

|

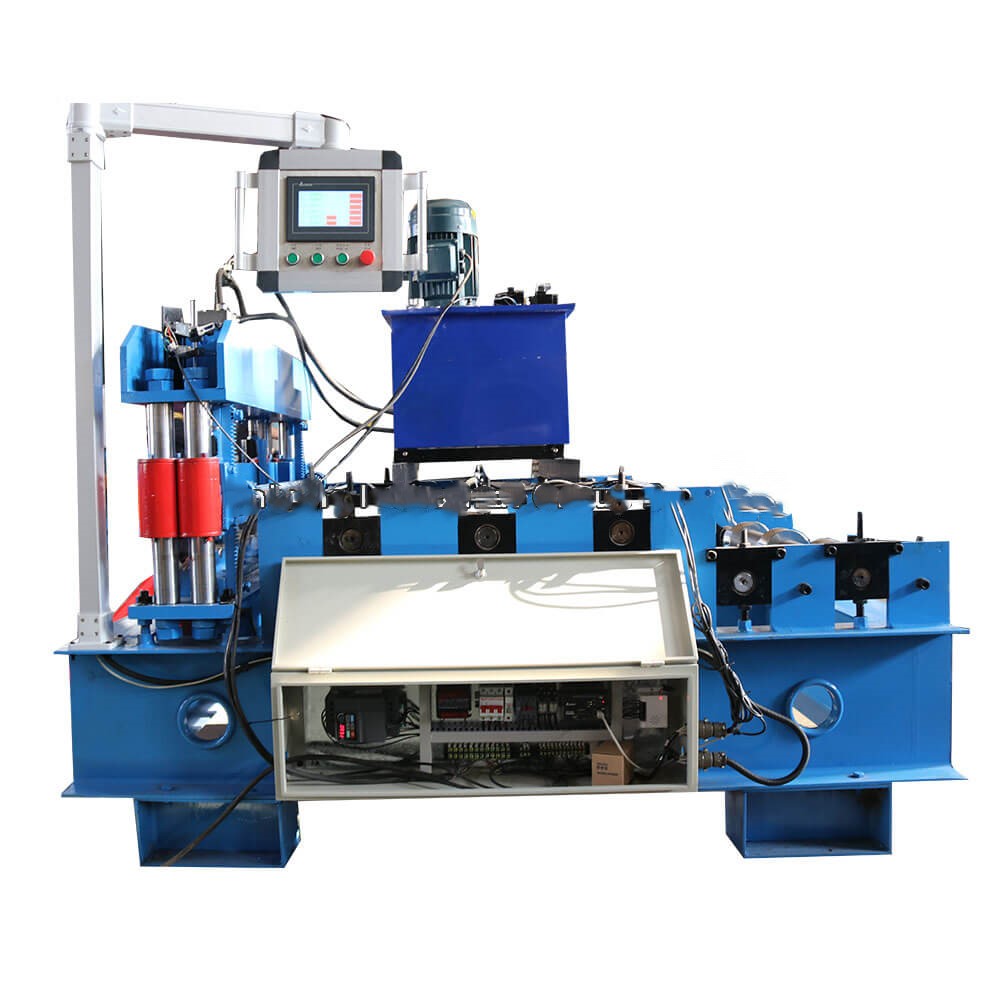

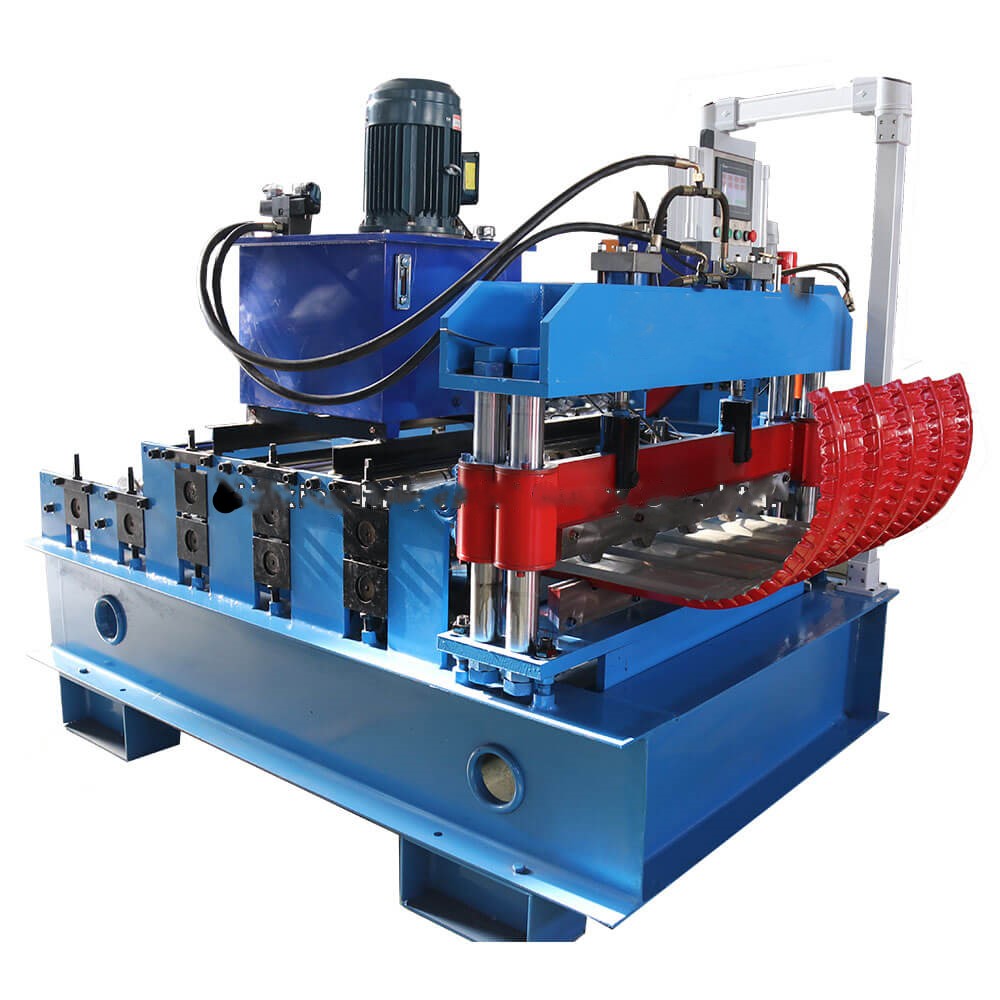

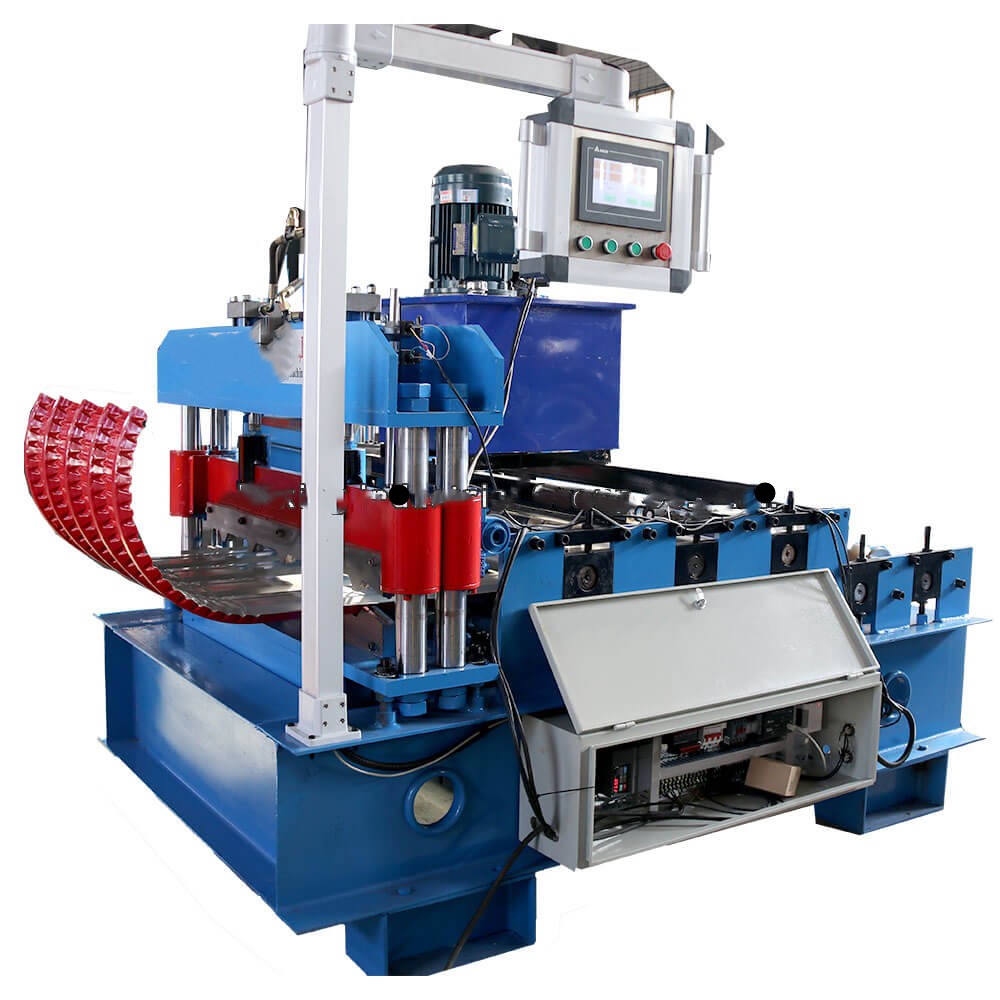

Main frame

|

Welded from 350mm H-beam.

|

|

Roller shaft diameter

|

70mm, solid shaft with retaining pad

|

|

shaft material

|

45# steel chrome 0.03mm

|

|

Transfer method

|

1.0 inch chain

|

|

Medium plate thickness

|

16mm

|

|

Main motor

|

3kw, Siemens Bede Motor

|

|

Hydraulic power station

|

4kw, gear pump: Shanghai Lichao

|

|

Cutter material

|

Cr12, heat treatment HR50-60

|

|

Cutting method

|

Hydraulic four-column cutting

|

|

Length tolerance

|

±2mm

|

|

PLC

|

High-precision computer control cabinet: Taiwan Delta; touch screen, frequency converter: |

|

Production speed

|

1.5-3 m/min

|

|

Voltage

|

380V, three-phase, 50 Hz

|

|

Feed width

|

914mm or or according to customer requirements

|

|

Number of rows

|

3 rows

|

|

Equipment size

|

6500*1350*1400mm

|

|

Pressing mold material

|

Cr12

|

|

Raw material thickness

|

0.28~0.8mm

|

Reviews

There are no reviews yet.