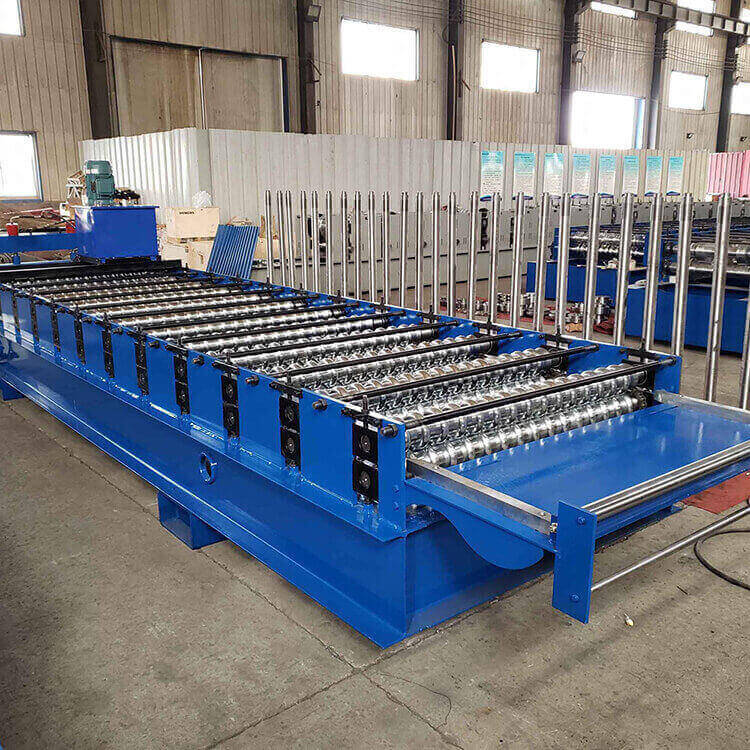

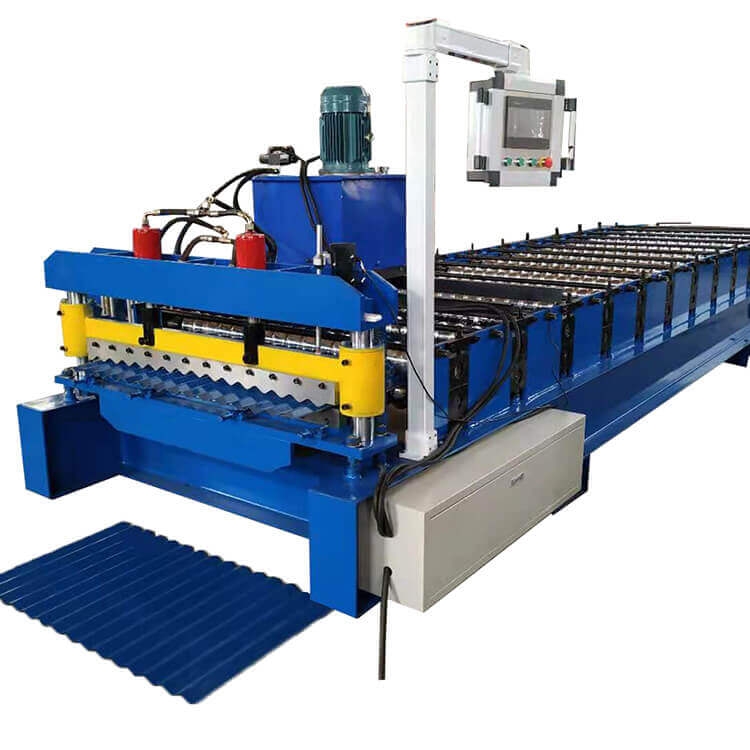

ROOF MAKING MACHINE

The Roof Making Machine is ultimate solution for seamless and efficient roof fabrication. Engineered for precision and speed, this machine is designed to streamline the roofing process, ensuring high-quality results with every use. Crafted for ease of operation, our Roof Making Machine is a must-have for roofing professionals and construction projects, delivering reliability and superior performance. Upgrade your roofing experience with our cutting-edge machine – where innovation meets durability for flawless roof construction.

This machine comes in various variation which includes: Trapezoidal Metal Sheet Roll Forming Machine, Design Trapezoid Roof Tile Making Machine, Aluminum Trapezoidal Sheet Roof Wall Panel Machine, Stepped Tile Corrugated Sheet Metal Roof Making, Color Steel Wave Roof Panel Roll Forming Machine, Metal Roofing Corrugated Sheet Making Machine, Aluminum Coil Metal r roof panel roll forming machine, Galvanized Corrugated Roof Sheet Making Machine.

Reviews

There are no reviews yet.