Spray Injection Patching Machine

Potholes on roads are a major concern for drivers and local municipal administrations. They bring traffic safety risks, may cause traffic accidents, threaten people’s lives, and cause damage to vehicles and property. In recent years, spray injection patching has become a quick and efficient way to repair road potholes, which is especially suitable for older and busy traffic arteries. With only a small staff, a pothole can be patched in minutes and immediately open to traffic. This method of operation minimizes the impact of road repairs on normal traffic.

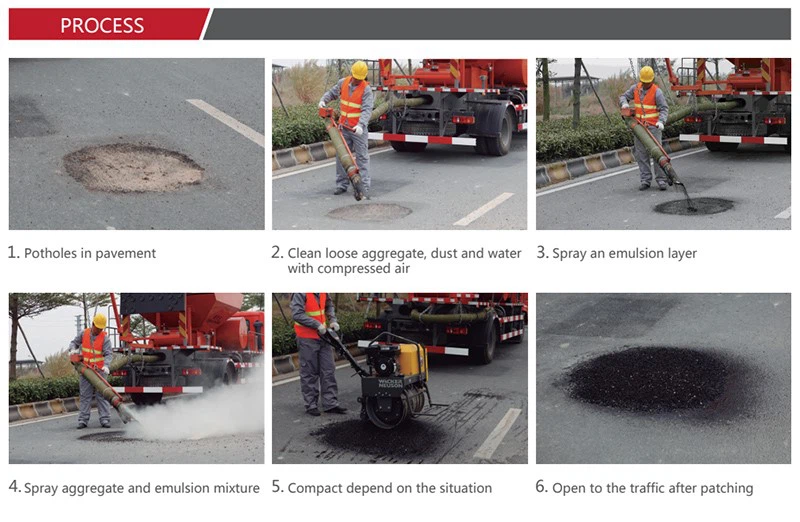

The principle of spray injection patching is very simple, that is, a mixture of aggregate and emulsion is directly injected into the pothole to complete the repair of the pavement. TOPM TM-4000 spray injection patching machine use high-pressure air to output emulsified asphalt and aggregate from different containers through pipelines, mix them evenly at the end, and then spray them into the trench at high speed. The whole process is simple and fast, no mixing required. In addition to potholes, this equipment can also treat road surface defects such as cracks, ruts, and shoulder damage. It can be said that one machine has multiple uses!

Reviews

There are no reviews yet.