Introduction to CNC machines in food processing

CNC machines are advanced tools that use computer programs to control their movements. In food processing, CNC machines are becoming increasingly popular due to their precision and efficiency. These machines automate tasks that were once done manually, like cutting, shaping, and milling food products. They ensure consistency in the production process, leading to higher quality and reduced waste. CNC’s are revolutionizing food processing by increasing productivity and allowing for more complex food designs.

Advantages of using CNC machines in food processing

They offer precise and consistent cuts in food processing, leading to less waste and higher efficiency. This technology ensures food products maintain their quality and standards throughout the production process. CNC’s reduce the risk of human error, increasing overall safety in food processing. The ability to program these machines allows for customization and flexibility in food processing, meeting specific demands with accuracy and speed.

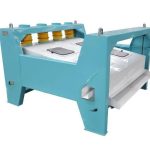

Types of CNC machines commonly used

CNC machines are often used in the food industry for tasks like cutting, shaping, and engraving food products. Common types include milling machines, lathes, and router machines. Each type has specific functions, with milling machines being versatile in shaping food products, lathes used for rotating and cutting operations, and router machines primarily for engraving or hollowing out food items. They play a crucial role in streamlining food processing operations, increasing efficiency, and ensuring precise outcomes.

Precision and efficiency in food processing with CNC machines

CNC’s in food processing ensure precise cutting and shaping of ingredients, leading to consistent product quality. These machines work efficiently, reducing waste and improving productivity in the food processing industry.

Impact of CNC machines on food quality and safety

CNC machines in food processing are revolutionizing the industry by enhancing food quality and safety. These machines ensure precision in cutting and shaping food products, leading to consistent quality. Moreover, automation reduces human error, minimizing the risk of contamination. Key benefits of CNC’s in food processing include:

- Ensuring precise cutting and shaping of food products.

- Reducing the risk of contamination by minimizing human error.

- Enhancing food quality and safety standards.

CNC machines are at the forefront of transforming food processing, promising a future of higher quality and safer food products.

Applications of CNC machines in different food processing stages

CNC machines are used in various stages of food processing to enhance efficiency and precision. Here’s how they are employed:

- Cutting: They excel in accurately cutting food ingredients into precise shapes and sizes, ensuring uniformity in the final product.

- Mixing: These machines can automate the mixing process, ensuring consistent blending of ingredients without human error.

- Packaging: CNC’s are utilized to package food products efficiently, ensuring proper sealing and labeling for consumer safety and convenience.

CNC machines play a pivotal role in streamlining food processing operations and ensuring high-quality end products.

Challenges and limitations of using CNC machines in food processing

CNC’s are not common in food processing due to the challenges they pose. Food safety concerns arise because these machines are difficult to clean thoroughly. Ingredients like nuts or seeds can clog the machines, causing operational issues. Maintenance costs can be high, and not all food shapes or textures are suitable for processing with CNC’s. Limited flexibility in adapting to new products may also hinder their widespread use in the food industry.

Innovations and trends shaping the future of CNC machines in food processing

CNC machines are revolutionizing food processing with their precision and efficiency. Here are some key innovations and trends influencing the future of CNC’s in the food processing industry:

- Automation: They are becoming more automated, reducing the need for manual labor and improving production accuracy.

- Customization: These machines are now able to handle a wide range of food products, allowing for more customization in food processing.

- Internet of Things (IoT): Integration of IoT technology with CNC’s enables remote monitoring and control, enhancing efficiency and reducing downtime.

- Smart Sensors: CNC’s now come equipped with advanced sensors that ensure consistency in processing and quality control.

- Adaptability: New machines are designed to be versatile and adaptable to various food processing requirements, increasing their utility across different settings.

Sustainability and environmental considerations with CNC machines

CNC machines in the food industry offer benefits beyond efficiency. They contribute to sustainability efforts by reducing food waste and energy consumption. These machines can operate with precision, minimizing errors and reducing the need for excess materials. Additionally, their automated processes result in fewer emissions, making them environmentally friendly.

Conclusion: The evolving role of CNC machines in revolutionizing food processing

CNC machines are changing the game in food processing. They bring precision and efficiency to the industry, making processes faster and more accurate. Companies are investing in these machines to stay competitive and meet the increasing demand for quality food products. As CNC technology continues to advance, we can expect even more innovations in food processing.

CNC’S FOR FOOD PROCESSING

0 Comments