Introduction to Manufacturing Machines in the Food Industry

Manufacturing machines in the food industry have completely transformed the way food is produced. These machines streamline the manufacturing process, making it faster and more efficient. They can handle large quantities of food, ensuring consistent quality and reducing human error. With the help of these machines, food production has become more cost-effective and scalable, meeting the growing demands of the market.

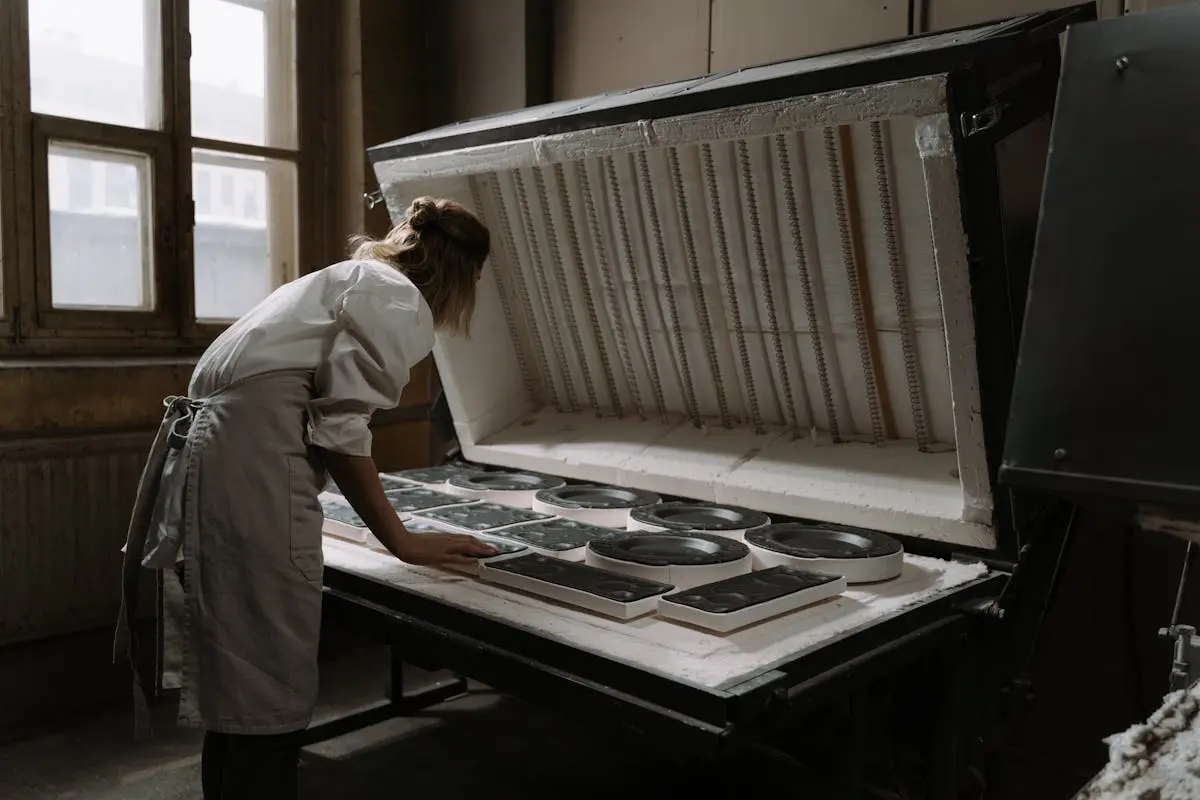

Manufacturing Machines

Streamlining Food Production Processes

Manufacturing machines have significantly enhanced the food industry by optimizing production processes. With these machines, companies can increase efficiency and output while maintaining quality standards. By automating tasks such as mixing, slicing, and packaging, manufacturers can save time and resources. Additionally, these machines ensure consistency in products, reducing errors and waste. Overall, manufacturing machines are transforming the food industry by streamlining production processes to meet the growing demands of the market.

Enhancing Food Safety with Manufacturing Machines

To enhance food safety, manufacturing machines play a crucial role in the food industry. Here are various ways these machines contribute to improving food safety:

- Automated processes reduce the risk of contamination and human error.

- Machines can accurately monitor and control food temperatures to prevent spoilage.

- Advanced packaging equipment helps maintain the freshness and integrity of products.

- Sanitation systems within machines ensure proper cleaning and hygiene standards.

- Quality control mechanisms guarantee adherence to safety regulations and standards, safeguarding consumer health and well-being.

Improving Food Quality Through Automated Processes

Automated processes in manufacturing machines ensure consistent food quality by controlling factors like temperature and mix ratios. This automation reduces human error, resulting in more precise and uniform food products. These machines also enable quicker production speeds, leading to fresher foods reaching consumers faster. Additionally, automation helps in maintaining hygiene standards by minimizing human contact with food during the manufacturing process. Industry experts suggest that these automated processes are transforming the food industry, enhancing food quality and safety for consumers.

Increasing Efficiency and Output in Food Manufacturing Industry

Using advanced machines in the food industry has led to a significant boost in efficiency and output. These machines can perform tasks quickly and accurately, leading to a faster production process. With the increased output, food manufacturers can meet the demands of consumers more effectively. Automation plays a crucial role in this revolution, allowing for streamlined processes and reduced errors. Additionally, modern equipment has enabled food manufacturers to produce a wider variety of products to cater to diverse consumer preferences. This advancement in technology is reshaping the way food is processed and distributed on a large scale.

Sustainable Practices and Environmental Impact

Manufacturing machines in the food industry are now incorporating sustainable practices to reduce their environmental impact. This includes implementing energy-efficient technologies, utilizing recycled materials, and minimizing waste production during the manufacturing process. By adopting these sustainable practices, food manufacturers are not only reducing their carbon footprint but also contributing to a healthier environment for future generations.

Types of Manufacturing Machines Used in the Food Industry

Manufacturing machines used in the food industry include mixers, filling machines, packaging machines, sorting machines, and labeling machines. Mixers are utilized for blending ingredients, filling machines fill packages with food products, packaging machines seal and package the food, sorting machines separate out products, and labeling machines apply labels to the packaging. Each type plays a crucial role in streamlining food production processes and ensuring efficiency in the industry.

Cost and Investment Considerations

Manufacturing machines can be a significant investment for businesses in the food industry. It’s important to consider the initial cost of the machines, as well as any ongoing maintenance expenses. Additionally, think about the return on investment – how quickly will the machines pay for themselves through increased efficiency and production? Don’t forget to factor in training costs for employees to operate the machines effectively. Lastly, research the warranty options available for the machines to protect your investment in case of any issues.

Challenges and Limitations of Implementing Manufacturing Machines

Implementing manufacturing machines in the food industry brings numerous benefits, but it also comes with challenges. Some of the limitations include the initial high investment costs required to set up the machinery. Additionally, training employees to operate and maintain these sophisticated machines can be a time-consuming process. Adapting the existing infrastructure to accommodate the new equipment may also pose challenges. Ensuring compliance with industry regulations and maintaining food safety standards are crucial aspects that must be addressed when integrating manufacturing machines.

Future Trends and Innovations in Food Industry Automation

Automation in the food industry is rapidly evolving with new technologies and innovations. Here’s a glimpse of what we can expect in the future:

- Increased Use of Robotics: Robots are being designed to handle various tasks like food preparation, packaging, and even delivery.

- Integration of Artificial Intelligence: AI is being utilized to optimize production processes, predict consumer trends, and enhance the overall efficiency of food manufacturing.

- IoT and Smart Sensors: The use of Internet of Things (IoT) devices and smart sensors is enabling real-time monitoring and control of production lines, leading to improved quality and cost-effectiveness.

- 3D Food Printing: This cutting-edge technology allows for the creation of customized food products with precise shapes and textures, opening up new avenues for creativity and personalization in the industry.

- Sustainable Practices: As the demand for eco-friendly products grows, food manufacturers are turning to sustainable practices such as reducing food waste, implementing energy-efficient processes, and using biodegradable packaging materials.

0 Comments