The Rise of the Industrial IoT

The Industrial Internet of Things (IIoT) is rapidly transforming the way businesses operate across all industries. Connected machines, equipped with sensors and transmitting data wirelessly, are creating a digital network that is revolutionizing how we monitor, manage, and optimize industrial processes. This blog explores the impact of IIoT on various industries, with a focus on how connected machinery is transforming businesses and improving efficiency.

Connected machines – The Power of Connectivity:

At the heart of IIoT lies the ability to connect machines to a central network. Sensors embedded in machinery collect real-time data on various parameters, such as performance, energy consumption, and environmental conditions. This data is then transmitted wirelessly to a cloud platform, where it can be analyzed, visualized, and utilized to gain valuable insights.

Transforming Industries:

The impact of IIoT is felt across various industries:

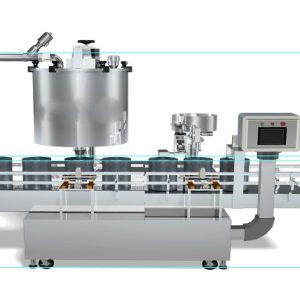

- Manufacturing: Connected machines enable real-time monitoring of production lines, predictive maintenance, and automated process optimization. This translates to increased production efficiency, reduced downtime, and improved product quality.

- Construction & Mining: Connected equipment provides valuable data on machine health, site conditions, and resource utilization. This allows construction & mining companies to optimize operations, improve safety, and make data-driven decisions throughout the project lifecycle.

- Energy & Utilities:IIoT facilitates smart grid management, allowing for real-time monitoring of energy consumption, demand forecasting, and automated optimization of energy distribution. This leads to reduced energy waste, improved grid efficiency, and more reliable power delivery.

- Logistics & Transportation: Connected vehicles and tracking systems enable real-time fleet management, optimized route planning, and predictive maintenance. This results in reduced fuel consumption, improved delivery times, and enhanced operational efficiency for logistics companies.

Benefits of Connected Machinery:

The integration of connected machinery offers a multitude of advantages for businesses:

- Improved Efficiency: Real-time data empowers businesses to identify inefficiencies and optimize processes, leading to increased productivity and reduced costs.

- Predictive Maintenance: By analyzing sensor data, businesses can predict potential equipment failures and perform maintenance proactively, minimizing downtime and maximizing asset uptime.

- Data-Driven Decision Making: The wealth of data collected by connected machines provides valuable insights that can be used to make informed decisions about production processes, resource allocation, and overall business strategy.

- Enhanced Safety: IIoT can improve safety in industries like construction & mining by monitoring environmental conditions and alerting workers to potential hazards.

The Future of Industrial Automation:

IIoT is just the beginning of a revolution in industrial automation. As technology continues to evolve, we can expect even greater levels of connectivity and data analysis. Imagine:

- Artificial intelligence (AI) playing a more prominent role in analyzing IIoT data to predict maintenance needs, optimize production processes in real-time, and automate decision-making.

- Machine learning algorithms learning from historical data to identify patterns and suggest further optimizations for even greater efficiency.

- The rise of “smart factories” where every aspect of production is connected and automated, leading to a new era of industrial efficiency and productivity.

The Rise of the Industrial IoT is a game-changer, and businesses that embrace connected machinery are poised to thrive in the competitive landscape. TopMachineries understands the importance of IIoT and offers a wide range of connected machinery solutions across various industries. Partner with us to harness the power of IIoT and transform your business for the future!

0 Comments